Hacksaw is mainly an alloy of iron and carbon with a small amount of zinc, manganese, nickel, etc., and is widely used in the construction industry because of its hardness. Hacksaw is a common tool for fitters, which can cut small-sized round steel, angle steel, flat steel and workpiece.

What are the precautions for using a hacksaw?

What are the structural characteristics of the hacksaw?

How to choose the right saw blade for your hacksaw?

What are the precautions for using a hacksaw?

When installing the hacksaw, the direction of the teeth should be in the forward direction. The saw face can be parallel to the plane of the saw frame or at a 90° angle as required.

Fix the item to be sawed with a bench vise in advance (sometimes step on it with one foot), in order to prevent the round pipe material from being flattened, two wooden blocks with grooves can be used to pad the round pipe On both sides, for very thin boards, you need to sandwich it with two boards and draw lines where you want to saw.

When using the hacksaw to start sawing the item, press the left thumb nail of the left hand to the left of the line, hold the handle of the saw with the right hand, make the saw blade beside the thumb, the sawtooth press on the line, and the saw blade and the material plane form a proper angle (eg around 15°).

What are the structural characteristics of the hacksaw?

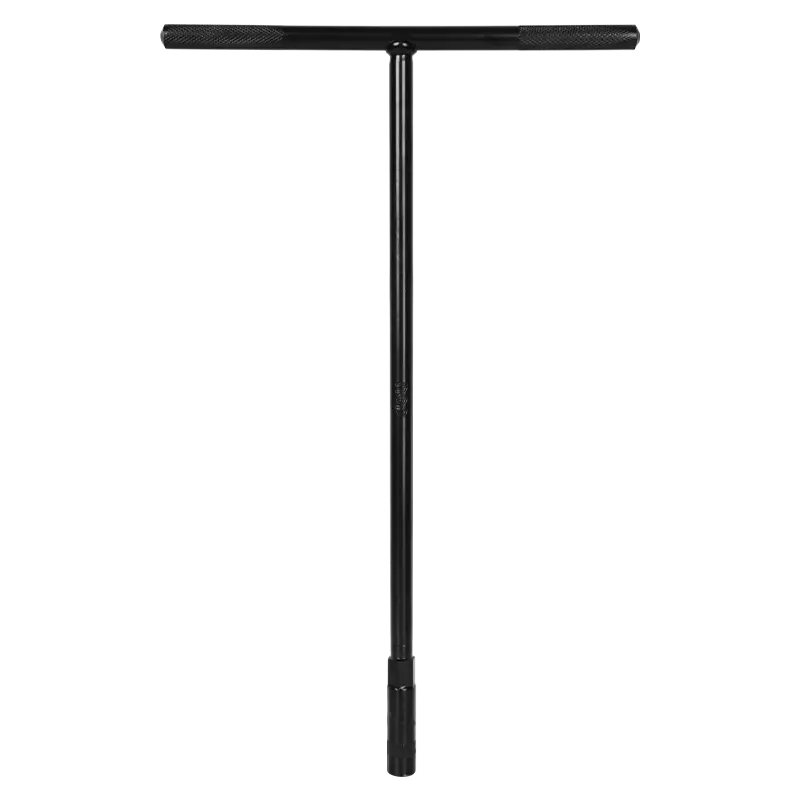

The hacksaw consists of a saw frame (commonly known as a saw bow) and a saw blade. When using, the saw blade is installed on the saw frame. Generally, the saw blade is installed with the tip of the tooth facing forward. However, if you find that it is easier to adze the teeth during use, put the tip of the tooth towards yourself. It can be installed in the same direction, which can relieve the adze and prolong the service life of the saw blade. After the hacksaw is used, the saw blade should be removed or the tension nut should be loosened, which can prevent the saw frame from being deformed, thereby prolonging the service life of the saw frame. There are two types of saw blades: single-sided teeth and double-sided teeth, which are divided into coarse teeth (14 teeth/25mm), medium teeth (18~24 teeth/25mm) and fine teeth (32 teeth/25mm), which are suitable for different materials. sawing.

How to choose the right saw blade for your hacksaw?

In order to improve the working efficiency of the hacksaw and avoid adze teeth, use a fine-toothed saw blade when sawing hard materials, a coarse-toothed saw blade when sawing soft materials, and a medium-toothed saw blade when sawing general materials. The thickness of the saw blade is 0.5~0.65mm, the width is 10~12mm, and the length is 200mm, 250mm and 300mm. There are two types of saw frames with fixed length and adjustable length. The adjustable length saw frame has three gears, which are respectively suitable for saw blades of three lengths. The factory is limited by the specifications of the purchased saw blades, and the two shorter gears are basically not used. They just swallow the moving parts when they are idle.

Deli Tools Global has various hacksaws that can provide the increasing of products, and make them more effective, reliable, and consistent.

EN

EN

jp

jp  ko

ko  fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  vi

vi  th

th  hi

hi  pl

pl  id

id  el

el